| Issue |

Mechanics & Industry

Volume 20, Number 2, 2019

|

|

|---|---|---|

| Article Number | 206 | |

| Number of page(s) | 9 | |

| DOI | https://doi.org/10.1051/meca/2019023 | |

| Published online | 24 May 2019 | |

Regular Article

Performance investigation of organic Rankine-vapor compression refrigeration integrated system activated by renewable energy

1

Mechanical Engineering Department, College of Engineering, Taif University, PO Box 888, Taif, Saudi Arabia

2

Mechanical Engineering Department, Faculty of Engineering, Assiut University, PO Box 71516, Assiut, Egypt

3

Electrical Engineering Department, College of Engineering, Taif University, PO Box 888, Taif, Saudi Arabia

4

Mechanical Engineering Department, Faculty of Engineering, King Abdulaziz University, PO Box 21589, Jeddah, Saudi Arabia

5

Physics and Engineering Mathematics Department, Faculty of Electronic Engineering, Menoufia University,

PO Box 32952, Menouf,

Egypt

6

Mathematics and Statistics Department, Faculty of Science, Taif University, PO Box 888, Taif, Saudi Arabia

* e-mail: bahaa_saleh69@yahoo.com

Received:

13

January

2018

Accepted:

22

March

2019

In this article, the performance and working fluid selection for an organic Rankine cycle-vapor compression refrigeration (ORC–VCR) integrated system activated by renewable energy is investigated. The performance of the system is described by the system coefficient of performance (COPS), and the refrigerant mass flow rate per kilowatt refrigeration capacity (m˙total). Twenty-three pure substances are proposed as working fluids for the integrated system. The basic integrated system performance is assessed and compared using the proposed working fluids. The basic VCR cycle works between 35 and 0 °C, while the basic ORC works between 35 and 100 °C. The impacts of different operating parameters such as the evaporator, the boiler, and the condenser temperatures on the ORC–VCR system performance are also examined. The results show that the cyclopentane accomplished the highest system performance under all investigated operating conditions. Accordingly, among the examined 23 working fluids, cyclopentane is the most appropriate working fluid for the integrated system from the viewpoints of environmental concerns and system performance. Nevertheless, due to its high flammability, further restrictions should be taken. The basic integrated system COPS, refrigeration effect, and the corresponding m˙total utilizing cyclopentane are 0.654, 361.3 kW, and 0.596 × 10−2 kg/(s kW), respectively.

Key words: Alternative working fluids / integrated system / organic Rankine cycle / vapor refrigeration cycle / renewable energy

© AFM, EDP Sciences 2019

1 Introduction

Low-grade thermal energy such as geothermal energy, solar energy, low-temperature waste heat from industrial plants, and exhaust gases from engines and turbines extensively exists in the world. Besides their renewable nature, they are also considered as free and clean energy sources since there is no additional direct carbon emission. Most of these heat sources cannot be used efficiently by the traditional power machines. In order to make better usage of low-temperature heat sources, researches on the combination of refrigeration and power systems have been conducted since the 1990s. Many systems arrangements have been suggested and inspected in the previous decade. These systems can transform low-grade heat to beneficial cooling or power energy. An organic Rankine cycle (ORC) driven by renewable energy and waste heat may be combined with vapor compression refrigeration (VCR) system for production of refrigeration or electricity [1,2].

The working fluids performance in an organic Rankine cycle-vapor compression refrigeration (ORC–VCR) integrated system is considerable. Numerous studies have been carried out to select the best fluid for the integrated system [3–7]. Saleh [4] suggested 10 substances as fluids for an ORC–VCR combined system. The results exhibited that R600 is the best fluid for the combined system. A parametric study and a regression analysis for a combined ORC and a cascade refrigeration system using natural refrigerants as working fluids were performed by Lizarte et al. [8]. The highest system coefficient of performance (COPS) value was 0.79. The performance and working fluid selection for a VCR–ORC system were examined by Asim et al. [9]. Based on thermodynamics, R600a-R123 was chosen as the fluid pair for the integrated system. They concluded that the COP of the system was improved from 3.10 to 3.54 compared with that of the VCR cycle subsystem. Cihan [10] performed a theoretical analysis of a combined system with R600, R600a, R245fa, and pentane as working fluids. The results showed that R601 is the most appropriate fluid for the combined system. Li et al. [11] evaluated the performance of an ORC–VCR system using R1270, R600, R290, and R600a. The results indicated that butane is the best fluid for the system with COPS of 0.47. Aphornratana and Sriveerakul [12] examined the performance of a combined system. With R134a, for a condenser temperature (Tcond) of 35 °C and an evaporator temperature (Teva) of −10 °C, the COPS was 0.125. Bu et al. [13,14] analyzed a combined system utilizing R245fa, R123, R600, R600a, R290, and R134a as working fluids. They concluded that R600a is the most appropriate fluid for the system. Han et al. [15] investigated experimentally an integrated power refrigeration system that utilizes an ammonia–water binary fluid. The COPS was 0.47 with cooling output of 11.7 kW. Wang et al. [16] performed an experimental study and theoretical analysis for an ORC–VCR system. The system attained a COPS value of approximately 0.5. Molés et al. [17] inspected an ORC–VCR system utilizing two working fluids for the ORC and two different fluids for the VCR. The results showed that the most suitable fluid for the power subsystem is R1336mzz(Z), while R1234ze(E) is the best fluid for the cooling subsystem. Nasir and Kim [18] examined the performance of seven working fluids, in an ORC–VCR system driven by low-grade thermal energy. They found that R600a is the most appropriate fluid for VCR cycle and R134a for ORC. Li et al. [19] performed energetic analysis for an ORC–VCR system using different working fluids. They concluded that R134a is the best fluid for the combined system. Kim and Perez-Blanco [20] performed a theoretical analysis for an ORC–VCR system using different working fluids. They concluded that R600 and R600a attained the highest system performance.

In this paper, the performance analysis of ORC–VCR integrated system for refrigeration or power production running with various working fluids is conducted. The inspected system is powered by a low-grade renewable heat source like waste heat or geothermal heat at around 115 °C. Twenty-three common and new pure hydrofluorocarbons (HFCs), hydrocarbons (HCs), fluorocarbons (FCs), hydrofluoroolefins (HFOs), and hydrofluoroethers (HFEs) are suggested and assessed as working fluids for the integrated system. The inspected substances are R161, RC318, butane (R600), pentane (R601), isobutane (R600a), isopentane (R601a), hexane (R602), R152a, perfluoropentane (C5F12), R236fa, R245ca, R236ea, R245fa, RE245cb2, isohexane (R602a), R1234ze(E), RE245fa2, RE170, RE347mcc, R365mfc, heptane (R603), octane (R604), and cyclopentane. The performance of the integrated system was assessed by the performance parameters, i.e., COPS and the refrigerant total mass flow rate per kilowatt refrigeration capacity ( ). The impacts of some operating parameters like the condenser, evaporator, and boiler temperatures on the system performance were also studied.

). The impacts of some operating parameters like the condenser, evaporator, and boiler temperatures on the system performance were also studied.

2 The system description and selection of working fluid

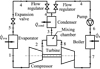

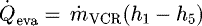

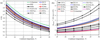

Figure 1 illustrates a scheme of the inspected integrated system, which includes two subsystems: the ORC, specified as 3-4-6-7-8-3, and the VCR cycle, specified as 1-2-3-4-5-1. The ORC contains turbine, pump, evaporator, and condenser. The VCR cycle consists of a compressor, an evaporator, a condenser, and a throttle devise. The features of the proposed system are as follows: (a) use the same fluid for both subsystems, (b) the turbine output power is equal to the compressor power, and (c) the system uses one condenser for the two subsystems. Two flow regulators were utilized to regulate flexibly the mass flow rate of the working fluid to VCR and ORC subsystems.

The working fluid selection for the integrated system is very important. An ideal fluid must accomplish both maximum system performance and lowest environmental concerns. Hydrochlorofluorocarbons (HCFCs) and chlorofluorocarbons (CFCs) are ozone-depleting fluids. Therefore, FCs and HFCs are used as alternative fluids for combined systems, ORC, and VCR cycle because they have zero ozone depletion potential (ODP) [1,21]. FCs and HFCs have high global warming potential (GWP), accordingly their use are controlled. Therefore, researches are still ongoing for alternative fluids, which may have lesser environmental concerns. As one of the proposals, HCs are considered as alternative fluids. HCs are environmentally friendly, have superior thermophysical properties, and have very low GWP [22]. The HCs are highly soluble in mineral oils, environmentally friendly, and chemically stable, but they are flammable. However, with proper safety protections, flammability will not be considered the largest challenge against HCs. HFEs are low toxic, nonflammable, have very low GWP, short atmospheric lifetime (ALT), and zero ODP; accordingly, they have been suggested as working fluids for thermal systems [23]. Moreover, many HFOs were recommended as working fluids due to their low environmental impacts [1,17].

The outline of temperature–entropy (T–s) diagram is a necessary property for fluid categorization. The fluids are categorized as isentropic, dry, and wet. For wet fluids, condensation takes place during the expansion in the turbine. This might be a reason for turbine blade erosion. Conversely, in the case of isentropic and dry fluids, there is no condensation. Consequently, in this paper all the assessed fluids are dry fluids except RE170, R161, and R152a, which are wet fluids. The thermodynamic properties and environmental and safety data of the inspected fluids are specified in Table 1 [24,25].

Figure 2a displays the T–s diagram of the inspected fluids; Figure 2b shows the T–s diagram of the integrated system. The processes in the system that are shown in Figure 2b can be described for each subsystem. The VCR cycle: Processes (1-2s and 1-2a) are isentropic and actual compression processes, process (8-2a-3) is an adiabatic mixing process, process (3-4) is a condensation process, process (4-5) is a throttling process, and process (5-1) is a vaporization process of the refrigerant through the evaporator. With respect to the ORC, processes (4-6S and 4-6a) are isentropic and actual pumping, process (6a-7) is vaporization process of the working fluid across the boiler, and processes (7-8S and 7-8a) are isentropic and actual expansion in the turbine.

|

Fig. 1 Scheme of the proposed ORC–VCR integrated system. |

Properties of the inspected fluids.

|

Fig. 2 (a) Inspected working fluids T–s diagrams. (b) T–s diagram of the integrated system. |

3 System energy analysis

The next assumptions are assumed to simplify the system modeling: (i) the system runs at a steady state, (ii) saturated states are supposed at the boiler, condenser, and evaporator exits, (iii) there is no heat loss in the pipelines, (iv) the pressure loss in the pipelines are neglected, and (v) flow losses, for example, the friction losses impacts and actual compression and expansion processes are taken into account by utilizing compressor, turbine, and pump efficiencies. The mathematical model of the integrated system displayed in Figure 1 is presented in the next sections.

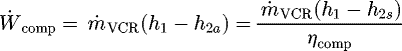

Concerning the VCR cycle, the required power for the compressor,  , can be calculated as follows:

, can be calculated as follows: (1)where

(1)where  is the mass flow rate of the fluid in the VCR, h1 is the specific enthalpy at the compressor entrance, h2s

and h2a

are the isentropic and actual specific enthalpies at the compressor outlet, respectively, and ηcomp is the compressor isentropic efficiency.

is the mass flow rate of the fluid in the VCR, h1 is the specific enthalpy at the compressor entrance, h2s

and h2a

are the isentropic and actual specific enthalpies at the compressor outlet, respectively, and ηcomp is the compressor isentropic efficiency.

The heat transfer rate to the refrigerant through the evaporator,  , can be expressed as

, can be expressed as (2)where h1 and h5 are the specific enthalpies at the outlet and entrance of the evaporator, respectively, in kJ/kg.

(2)where h1 and h5 are the specific enthalpies at the outlet and entrance of the evaporator, respectively, in kJ/kg.

The VCR cycle coefficient of performance, COPVCR, is expressed as (3)

(3)

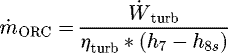

Concerning the ORC, the power output from the turbine,  , is just sufficient to power the compressor:

, is just sufficient to power the compressor: (4)

(4)

The working fluid mass flow rate in the ORC,  , can be expressed as

, can be expressed as (5)where h7 is specific enthalpy at the turbine entrance, h8s

is the isentropic specific enthalpy at the exit of the turbine, and ηturb is the turbine isentropic efficiency.

(5)where h7 is specific enthalpy at the turbine entrance, h8s

is the isentropic specific enthalpy at the exit of the turbine, and ηturb is the turbine isentropic efficiency.

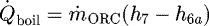

The rate of heat transfer in the boiler,  , can be written as

, can be written as (6)

(6)

where h6a is the actual specific enthalpy at the boiler inlet, and h7 is the specific enthalpy at the boiler outlet.

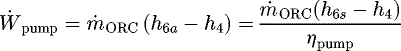

The required power to the pump,  , can be expressed as

, can be expressed as (7)where h6s

and h6a

are the isentropic and actual enthalpies at the pump outlet, respectively, h4 is the enthalpy at the entrance of the pump, and ηpump is the efficiency of the pump.

(7)where h6s

and h6a

are the isentropic and actual enthalpies at the pump outlet, respectively, h4 is the enthalpy at the entrance of the pump, and ηpump is the efficiency of the pump.

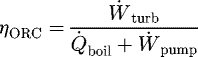

The thermal efficiency of the ORC, ηORC, is represented as (8)

(8)

The heat transfer rate from the fluid in the condenser,  , can be expressed as

, can be expressed as (9)

(9)

The COP

S

of the integrated ORC–VCR system can be written as (10)

(10)

The working fluid total mass flow rate per kW cooling capacity,  , in kg/(s · kW) is expressed as

, in kg/(s · kW) is expressed as (11)

(11)

A computer program is constructed to compute the performance of the integrated system using various fluids under different operating parameters and to examine the impacts of many working conditions on the performance of the system. The NIST REFPROP 9.1 database [26] was applied to get the properties of the investigated fluids. The basic values of the integrated system operating conditions and their ranges are specified in Table 2. The uppermost temperature of the boiler (Tboil) was kept constant at 100 °C, which is permitted to use renewable energy heat source at ∼115 °C.

Operating conditions basic values.

4 Results and discussion

The performance of an ORC–VCR integrated system activated by low-grade renewable energy source utilizing various fluids is assessed. The investigated fluids are R161, RC318, R600, R600a, R601a, R601, R602, perfluoropentane, R152a, R236fa, R1234ze(E), R245ca, R236ea, R245fa, RE245cb2, R602a, RE245fa2, RE170, RE347mcc, R365mfc, R603, R604, and cyclopentane. The critical temperatures of the inspected fluids exist between 102.1 °C for R161 and 296.17 °C for R604, as shown in Table 1.

A performance comparison of the basic integrated system utilizing all inspected fluids is presented in Table 3. Additionally, the T–s diagram type, cooling effect ( ), the power output from the turbine, and the actual quality at the turbine outlet (x8a) are also specified in Table 3. The outcomes in Table 3 were gotten utilizing the basic values of the operating conditions as specified in Table 2. It is detected from the results in Table 3 that cyclopentane has the highest COP

S

,

), the power output from the turbine, and the actual quality at the turbine outlet (x8a) are also specified in Table 3. The outcomes in Table 3 were gotten utilizing the basic values of the operating conditions as specified in Table 2. It is detected from the results in Table 3 that cyclopentane has the highest COP

S

,  , and the lowest

, and the lowest  values. These values are 0.654, 361.3 kW, and 0.596 × 10−2 kg/(s · kW), respectively. Conversely, perfluoropentane with the uppermost molecular mass accomplishes the lower most COP

S

,

values. These values are 0.654, 361.3 kW, and 0.596 × 10−2 kg/(s · kW), respectively. Conversely, perfluoropentane with the uppermost molecular mass accomplishes the lower most COP

S

,  , values and the uppermost

, values and the uppermost  . These values are 0.43, 63.57 kW, and 3.2 × 10−2 kg/(s · kW), respectively. Accordingly, from the energetic analysis viewpoint, cyclopentane may be considered as a promising fluid for the integrated system.

. These values are 0.43, 63.57 kW, and 3.2 × 10−2 kg/(s · kW), respectively. Accordingly, from the energetic analysis viewpoint, cyclopentane may be considered as a promising fluid for the integrated system.

The impacts of some selected working parameters such as Tcond, Teva, and Tboil on the performance of the integrated system are explained in the next sections. In each subsection, the parameter whose impact is inspected varied within the range listed in Table 2 whereas the remaining operating conditions are kept constant and equal to the basic values presented in Table 2. The results show that all inspected operating conditions have similar impacts on the integrated system performance for all inspected fluids. Consequently, in the following figures, only some selected fluids from the 23 inspected fluids were drawn as examples.

Basic ORC–VCR integrated system performance using all examined fluids.

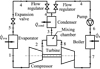

4.1 Evaporator temperature impact on the integrated system performance

The alterations of COP

S

and  with Teva using some selected investigated fluids in the basic integrated system are shown in Figure 3. As observed from Figure 3a, the COP

S

increases with the increase of Teva for all fluids. The alteration of Teva has no impact on ORC. Thus, ηORC is unchanged with the variation of Teva. The evaporator saturation pressure increases with the increase of Teva for all fluids. This leads to decline of

with Teva using some selected investigated fluids in the basic integrated system are shown in Figure 3. As observed from Figure 3a, the COP

S

increases with the increase of Teva for all fluids. The alteration of Teva has no impact on ORC. Thus, ηORC is unchanged with the variation of Teva. The evaporator saturation pressure increases with the increase of Teva for all fluids. This leads to decline of  with constant Tcond. Conversely, the increase of Teva enhances the refrigeration effect. Both impacts enhance the COPVCR. Based on equation (10), this results in improvement in the COP

S

as Teva increases. As Teva varies from −15 up to 15 °C, the COP

S

improves nearly 230% for all examined fluids.

with constant Tcond. Conversely, the increase of Teva enhances the refrigeration effect. Both impacts enhance the COPVCR. Based on equation (10), this results in improvement in the COP

S

as Teva increases. As Teva varies from −15 up to 15 °C, the COP

S

improves nearly 230% for all examined fluids.

The variations of  as function of the Teva for the selected fluids in the basic system are exhibited in Figure 3b. As Teva increases and with the assumption of fixed

as function of the Teva for the selected fluids in the basic system are exhibited in Figure 3b. As Teva increases and with the assumption of fixed  , the required

, the required  declines. According to the assumption

declines. According to the assumption  decreases as Teva increases. The turbine-specific work is kept constant as Teva changes. Based on equation (5), due to reducing

decreases as Teva increases. The turbine-specific work is kept constant as Teva changes. Based on equation (5), due to reducing  and fixed turbine-specific work,

and fixed turbine-specific work,  must decline as Teva rises. Therefore,

must decline as Teva rises. Therefore,  decreases as Teva increases, as shown in Figure 3b. The alteration of

decreases as Teva increases, as shown in Figure 3b. The alteration of  with Teva is almost linear, as seen in Figure 3b. With the change of Teva from −15 °C to 15 °C, the average decline of

with Teva is almost linear, as seen in Figure 3b. With the change of Teva from −15 °C to 15 °C, the average decline of  is approximately 49% for all investigated fluids. Among the 23 investigated fluids, cyclopentane accomplishes the uppermost COP

S

and the lowest

is approximately 49% for all investigated fluids. Among the 23 investigated fluids, cyclopentane accomplishes the uppermost COP

S

and the lowest  for all inspected Teva values. Conversely, perfluoropentane attains the lowest COP

S

and the highest

for all inspected Teva values. Conversely, perfluoropentane attains the lowest COP

S

and the highest  for all inspected Teva values.

for all inspected Teva values.

|

Fig. 3 Impact of Teva on the COP

S

(a) and |

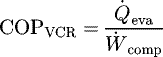

4.2 Boiler temperature impact on the integrated system performance

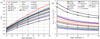

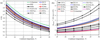

The influence of Tboil on the basic integrated system performance using some investigated fluids is shown in Figure 4. The COP

S

alterations with the variations of Tboil are shown in Figure 4a. The COP

S

enhances as Tboil improves. The enhancement in Tboil has no influence on the COPVCR as  and

and  are kept constant. The turbine-specific work rises as Tboil increases. Since it is assumed that

are kept constant. The turbine-specific work rises as Tboil increases. Since it is assumed that  , and the truth that the

, and the truth that the is kept constant as Tboil increases,

is kept constant as Tboil increases,  should reduce as Tboil increases. The increase of Tboil results in enhancement of the specific heat added to the boiler. The trends of both

should reduce as Tboil increases. The increase of Tboil results in enhancement of the specific heat added to the boiler. The trends of both  and boiler-specific heat with Tboil lead to decrease of

and boiler-specific heat with Tboil lead to decrease of  as Tboil increases. With the constant

as Tboil increases. With the constant  , decline of

, decline of  , and the increase of Tboil and based on equation (8), ηORC is enhanced. This results in the development of COP

S

, as shown in Figure 4a. As seen from Figure 4a, the COP

S

for all examined fluids at 100 °C Tboil are approximately double of those at 60 °C Tboil.

, and the increase of Tboil and based on equation (8), ηORC is enhanced. This results in the development of COP

S

, as shown in Figure 4a. As seen from Figure 4a, the COP

S

for all examined fluids at 100 °C Tboil are approximately double of those at 60 °C Tboil.

Figure 4b shows  as function of Tboil for some investigated fluids in the basic system. With the assumption that

as function of Tboil for some investigated fluids in the basic system. With the assumption that  is kept constant and

is kept constant and  declines as Tboil increases,

declines as Tboil increases,  reduces as Tboil increases, as shown in Figure 4b. Figure 4 also shows that among all inspected fluids, cyclopentane attains the uppermost COP

S

and the lowermost

reduces as Tboil increases, as shown in Figure 4b. Figure 4 also shows that among all inspected fluids, cyclopentane attains the uppermost COP

S

and the lowermost  for all examined Tboil. Conversely, perfluoropentane accomplishes the lowest COP

S

and the highest

for all examined Tboil. Conversely, perfluoropentane accomplishes the lowest COP

S

and the highest  .

.

|

Fig. 4 Impact of Tboil on the COP

S

(a) and |

4.3 Condenser temperature impact on the integrated system performance

Figure 5 shows the Tcond impact on the performance of basic integrated system. Figure 5a shows the alteration of COP

S

against Tcond for some examined fluids. As observed from Figure 5a, Tcond has a great impact on the COP

S

. This is because of the impact of Tcond on the ORC and VCR subsystems. The rejected heat is constrained by Tcond, which is an additional restriction to improve the system efficiency in addition to Tboil. Huge values of total heat rejected are unwanted to achieve large efficiencies in the two subcycles. Both pressure and enthalpy at the exit of the compressor increase with the enhancement of Tcond with constant temperature and pressure at the entrance of the compressor. This results in a decline of  , increase of

, increase of  , and decline of COPVCR. Moreover, the increase of Tcond leads to increase of

, and decline of COPVCR. Moreover, the increase of Tcond leads to increase of  because of the assumption of

because of the assumption of  and accordingly the

and accordingly the  increase of

increase of  to attain the assumption. The increase of

to attain the assumption. The increase of  results in increase of

results in increase of  . But the rate at which

. But the rate at which  increases is greater than that of

increases is greater than that of  , which results in the decline of ηORC. Based on equation (10), the decrease of both COPVCR and ηORC results in decrease of COP

S

. As noticed in Figure 5a, the COPS declines as Tcond increases for all inspected fluids. As Tcond changes from 25 to 50 °C, COP

S

declines by nearly 69% for all examined fluids. In comparison to all studied fluids, cyclopentane achieves the maximum thermal efficiency, while perfluoropentane attains the lowest thermal efficiency for all inspected Tcond. With Tcond equal to 35 °C and the basic values for the remaining operating conditions, COP

S

utilizing cyclopentane is larger than that those of perfluoropentane by about 34.3%.

, which results in the decline of ηORC. Based on equation (10), the decrease of both COPVCR and ηORC results in decrease of COP

S

. As noticed in Figure 5a, the COPS declines as Tcond increases for all inspected fluids. As Tcond changes from 25 to 50 °C, COP

S

declines by nearly 69% for all examined fluids. In comparison to all studied fluids, cyclopentane achieves the maximum thermal efficiency, while perfluoropentane attains the lowest thermal efficiency for all inspected Tcond. With Tcond equal to 35 °C and the basic values for the remaining operating conditions, COP

S

utilizing cyclopentane is larger than that those of perfluoropentane by about 34.3%.

The change of  with Tcond for all inspected fluids in the basic integrated system is shown in Figure 5b. As Tcond increases, the required

with Tcond for all inspected fluids in the basic integrated system is shown in Figure 5b. As Tcond increases, the required  increases, and to achieve the assumption of

increases, and to achieve the assumption of  (Eq. (4)), the

(Eq. (4)), the  should be increased. With the increase of

should be increased. With the increase of  and with fixed

and with fixed  ,

,  increases as Tcond increases. The common tendency in Figure 5b is increase of

increases as Tcond increases. The common tendency in Figure 5b is increase of  with the increase of Tcond for all inspected fluids. In comparison to all inspected fluids, the lowermost

with the increase of Tcond for all inspected fluids. In comparison to all inspected fluids, the lowermost  was achieved by the bottommost molecular mass fluids. Conversely, the fluids with the uppermost molecular mass attained the highest

was achieved by the bottommost molecular mass fluids. Conversely, the fluids with the uppermost molecular mass attained the highest  for all inspected Tcond. At Tcond equal to 50 and 25 °C,

for all inspected Tcond. At Tcond equal to 50 and 25 °C,  values in the case of perfluoropentane are nearly 6.1 and 5.1 times those of cyclopentane, respectively. As Tcond changes from 25 to 50 °C using cyclopentane,

values in the case of perfluoropentane are nearly 6.1 and 5.1 times those of cyclopentane, respectively. As Tcond changes from 25 to 50 °C using cyclopentane,  increases by almost 132%.

increases by almost 132%.

To summarize, among all inspected fluids, cyclopentane achieves the highest COP

S

and the lowest  under all inspected working parameters. Conversely, perfluoropentane attains the lowest COP

S

and the highest

under all inspected working parameters. Conversely, perfluoropentane attains the lowest COP

S

and the highest  under all inspected working parameters. Therefore, cyclopentane may be considered the most convenient fluid for the integrated system. Cyclopentane is strongly flammable, which is the main challenge contrary to its usage. However, with additional safety cautions, the flammability will not be the problem in using cyclopentane.

under all inspected working parameters. Therefore, cyclopentane may be considered the most convenient fluid for the integrated system. Cyclopentane is strongly flammable, which is the main challenge contrary to its usage. However, with additional safety cautions, the flammability will not be the problem in using cyclopentane.

|

Fig. 5 Impact of Tcond on the COP

S

(a) and |

5 Conclusions

The performance and working fluid selection for an ORC–VCR integrated system powered by renewable energy was studied. Numerous pure fluids, i.e., R161, RC318, R600, R601, R600a, R601a, R152a, R602, perfluoropentane, R245ca, R236fa, R245fa, R236ea, RE245cb2, R602a, R1234ze(E), RE245fa2, RE170, RE347mcc, R365mfc, R603, R604, and cyclopentane, were suggested as working fluids for the integrated system. The impacts of some operating conditions, i.e., the evaporator, condenser, and boiler temperatures, on the performance of the integrated system were also examined.

The results show that the highest thermal efficiency and the lowest mass flow rate were achieved by cyclopentane. Among the 23 inspected fluids, cyclopentane is the best working fluid for the integrated system to recapture low-grade renewable energy with a temperature between 75 and 115 °C. Since cyclopentane is highly flammable, supplementary precautions must be taken. The subsequent results were acquired using cyclopentane as working fluid. The COP

S

and  values at 100 °C boiler temperature equal 2.18 and 0.57 times, respectively, those at boiler temperature of 60 °C. The COP

S

and

values at 100 °C boiler temperature equal 2.18 and 0.57 times, respectively, those at boiler temperature of 60 °C. The COP

S

and  values at 25 °C condenser temperature equal 2.84 and 0.43 times, respectively, those at condenser temperature of 50 °C. The COP

S

and

values at 25 °C condenser temperature equal 2.84 and 0.43 times, respectively, those at condenser temperature of 50 °C. The COP

S

and  values at 15 °C evaporator temperature equal 3.26 and 0.47 times those at evaporator temperature of −15 °C, respectively. When the condenser temperature equals 25 °C and the remaining parameters at their basic values, the highest COP

S

and the corresponding

values at 15 °C evaporator temperature equal 3.26 and 0.47 times those at evaporator temperature of −15 °C, respectively. When the condenser temperature equals 25 °C and the remaining parameters at their basic values, the highest COP

S

and the corresponding  are 1.05 and 0.44 × 10−2 kg/(s · kW), respectively.

are 1.05 and 0.44 × 10−2 kg/(s · kW), respectively.

Acknowledgments

This study is supported by Taif University under research grant 1-439-6067. The authors would like to thank Taif University for financial support.

References

- W. Sun, X. Yue, Y. Wang, Exergy efficiency analysis of ORC (organic Rankine cycle) and ORC based combined cycles driven by low-temperature waste heat, Energy Convers. Manage. 135 (2017) 63–73 [CrossRef] [Google Scholar]

- B. Saleh, Energy and exergy analysis of an integrated organic Rankine cycle-vapor compression refrigeration system, Appl. Therm. Eng. 141 (2018) 697–710 [Google Scholar]

- C. Yue, F. You, Y. Huang, Thermal and economic analysis of an energy system of an ORC coupled with vehicle air conditioning, Int. J. Refrig. 64 (2016) 152–167 [Google Scholar]

- B. Saleh, Parametric and working fluid analysis of a combined organic Rankine-vapor compression refrigeration system activated by low-grade thermal energy, J. Adv. Res. 7 (2016) 651–660 [CrossRef] [PubMed] [Google Scholar]

- H. Chang, Z. Wan, Y. Zheng, X. Chen, S. Shu, Z. Tu, S.H. Chan, Energy analysis of a hybrid PEMFC-solar energy residential micro CCHP system combined with an organic Rankine cycle and vapor compression cycle, Energy Convers. Manage. 142 (2017) 374–384 [CrossRef] [Google Scholar]

- K. Braimakis, A. Thimo, S. Karellas, Technoeconomic analysis and comparison of a solar-based biomass ORC-VCC system and a PV heat pump for domestic trigeneration, J. Energy Eng. 143 (2017) 04016048 [CrossRef] [Google Scholar]

- D. Wu, L. Aye, T. Ngo, P. Mendis, Optimisation and financial analysis of an organic Rankine cycle cooling system driven by facade integrated solar collectors, Appl. Energy 185 (2017) 172–182 [Google Scholar]

- R. Lizarte, M.E. Palacios-Lorenzo, J.D. Marcos, Parametric study of a novel organic Rankine cycle combined with a cascade refrigeration cycle (ORC-CRS) using natural refrigerants, Appl. Therm. Eng. 127 (2017) 378–389 [Google Scholar]

- M. Asim, M.K.H. Leung, Z. Shan, Y. Li, D.Y.C. Leung, M. Ni, Thermodynamic and thermo-economic analysis of integrated organic Rankine cycle for waste heat recovery from vapor compression refrigeration cycle, Energy Procedia 143 (2017) 192–198 [Google Scholar]

- E. Cihan, Cooling performance investigation of a system with an organic Rankine cycle using waste heat sources, J. Therm. Sci. Technol. 34 (2014) 101–109 [Google Scholar]

- H. Li, X. Bu, L. Wang, Z. Long, Y. Lian, Hydrocarbon working fluids for a Rankine cycle powered vapor compression refrigeration system using low-grade thermal energy, Energy Build. 65 (2013) 167–172 [Google Scholar]

- S. Aphornratana, T. Sriveerakul, Analysis of a combined Rankine-vapour compression refrigeration cycle, Energy Convers. Manage. 51 (2010) 2557–2564 [CrossRef] [Google Scholar]

- X. Bu, L. Wang, H. Li, Performance analysis and working fluid selection for geothermal energy-powered organic Rankine-vapor compression air conditioning, Geothermal Energy 1–2 (2013) 1–14 [Google Scholar]

- X. Bu, L. Wang, H. Li, Working fluids selection for fishing boats waste heat powered organic Rankine-vapor compression ice maker, Heat Mass Transf. 50 (2014) 1479–1485 [Google Scholar]

- W. Han, Q. Chen, L. Sun, S. Mac, T. Zhao, D. Zheng, H. Jin, Experimental studies on a combined refrigeration/power generation system activated by low-grade heat, Energy 74 (2014) 59–66 [CrossRef] [Google Scholar]

- H. Wang, R. Peterson, K. Harada, E. Miller, R. Ingram-Goble, L. Fisher, Performance of a combined organic Rankine cycle and vapor compression cycle for heat activated cooling, Energy 36 (2011) 447–458 [CrossRef] [Google Scholar]

- F. Molés, J. Navarro-Esbrí, B. Peris, A. Mota-Babiloni, K. Kontomaris, Thermodynamic analysis of a combined organic Rankine cycle and vapor compression cycle system activated with low temperature heat sources using low GWP fluids, Appl. Therm. Eng. 87 (2015) 444–453 [Google Scholar]

- M.T. Nasir, K.C. Kim, Working fluids selection and parametric optimization of an organic Rankine cycle coupled vapor compression cycle (ORC-VCC) for air conditioning using low grade heat, Energy Build. 129 (2016) 378–395 [Google Scholar]

- Y.R. Li, X.Q. Wang, X.P. Li, J.N. Wang, Performance analysis of a novel power/refrigerating combined-system driven by the low-grade waste heat using different refrigerants, Energy 73 (2014) 543–553 [CrossRef] [Google Scholar]

- K.H. Kim, H. Perez-Blanco, Performance analysis of a combined organic Rankine cycle and vapor compression cycle for power and refrigeration cogeneration, Appl. Therm. Eng. 91 (2015) 964–974 [Google Scholar]

- B. Saleh, Performance analysis and working fluid selection for ejector refrigeration cycle, Appl. Therm. Eng. 107 (2016) 114–124 [Google Scholar]

- A.H. Antunes, E.P. Filho, Experimental investigation on the performance and global environmental impact of a refrigeration system retrofitted with alternative refrigerants, Int. J. Refrig. 70 (2016) 119–127 [Google Scholar]

- E.K. Goharshadi, F. Moosavi, Prediction of thermodynamic properties of some hydrofluoroether refrigerants using a new equation of state, Fluid Phase Equilib. 238 (2005) 112–119 [Google Scholar]

- J.M. Calm, G.C. Hourahan, Physical, safety, and environmental data summary for current and alternative refrigerants, in: Proceedings of the 23rd International Congress of Refrigeration, Prague, Czech Republic, ID: 915, 2011, pp. 1–22 [Google Scholar]

- J.M. Calm, ARTI Refrigerant Database: Data Summaries − Volume 1: Single-Compound Refrigerants, Air-Conditioning and Refrigeration Technology Institute, Arlington, VA, 1999 [Google Scholar]

- E.W. Lemmon, M.L. Huber, M.O. McLinden, Reference Fluid Thermodynamic and Transport Properties (REFPROP): Version 9.1, National Institute of Standards and Technology (NIST), Boulder, CO, 2013 [Google Scholar]

Cite this article as: B. Saleh, A.A. Aly, A.F. Alogla, A.M. Aljuaid, M.M. Alharthi, K.I.E. Ahmed, Y.S. Hamed, Performance investigation of organic Rankine-vapor compression refrigeration integrated system activated by renewable energy, Mechanics & Industry 20, 206 (2019)

All Tables

All Figures

|

Fig. 1 Scheme of the proposed ORC–VCR integrated system. |

| In the text | |

|

Fig. 2 (a) Inspected working fluids T–s diagrams. (b) T–s diagram of the integrated system. |

| In the text | |

|

Fig. 3 Impact of Teva on the COP

S

(a) and |

| In the text | |

|

Fig. 4 Impact of Tboil on the COP

S

(a) and |

| In the text | |

|

Fig. 5 Impact of Tcond on the COP

S

(a) and |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.